PLASMA CLEANING

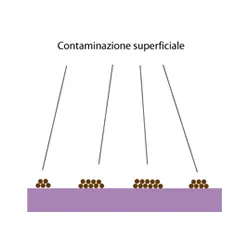

Plasma cleaning is an advanced technology used in various industries to treat the surfaces of materials such as metals, polymers, glass, and ceramics. By introducing a substrate into a plasma cleaner, the surface can be thoroughly cleaned through a combination of physical and chemical mechanisms. Physically, the plasma acts by microblasting the surface with ions, effectively removing contaminants. Chemically, it modifies any potential organic thin layers, converting them into gases that are then expelled from the system.

This plasma cleaning process allows for the complete removal of both organic and inorganic contaminants from the substrate. Unlike traditional cleaning methods that rely on chemical solvents or mechanical abrasion, plasma cleaning is a highly precise, eco-friendly solution that minimizes environmental impact. Additionally, this process improves surface adhesion for subsequent manufacturing steps.

Thanks to its dual-action cleaning capability—physical ion bombardment and chemical modification—plasma cleaners ensure deep and efficient surface preparation. This makes plasma cleaning an indispensable tool for industries that demand high precision and cleanliness in their production processes.

How plasma cleaning works

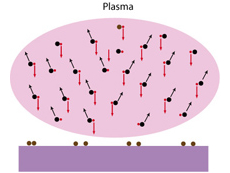

The plasma cleaning process begins by generating a plasma, usually using gases like argon, oxygen, or a mixture of both, which are energized by an electric field. This energy ionizes the gas, creating an electric plasma made up of reactive ions, electrons, and neutral particles.

Once the substrate is placed into the plasma cleaner, the high-energy ions bombard the surface, removing contaminants through a process known as ion bombardment or microblasting. Simultaneously, reactive species in the plasma chemically interact with any organic residues, converting them into gaseous by products like carbon dioxide or water vapor. These gases are then safely evacuated from the cleaning chamber.

This dual-action mechanism—physical and chemical—ensures a highly efficient cleaning process, leaving the surface completely free of unwanted particles and organic layers.

Advantages of plasma cleaning

Plasma cleaning offers a series of significant advantages over traditional methods, such as chemical or mechanical cleaning. First of all, it is a high-accuracy cleaning method: plasma cleaning offers high precision, reaching even the smallest crevices and microscopic surfaces that traditional methods cannot access.

Moreover, since no harsh solvents or chemicals are used, plasma cleaners is eco-friendly: it presents a greener alternative, reducing both chemical waste and environmental impact.

This process also works at low temperatures, making it suitable for heat-sensitive materials like polymers and certain electronics.

Eventually, the plasma cleaning process enhances surface energy, which improves adhesion for coatings, bonding, and other post-cleaning processes, increasing product reliability.

Thanks to all these advantages, plasma cleaning can be applied to a wide range of materials and surfaces, making it useful across multiple industries.

Applications of plasma cleaning

The plasma cleaning process has widespread applications across many fields, including:

Electronics: Essential for removing organic contaminants from printed circuit boards (PCBs) and other sensitive components, plasma cleaning ensures optimal functionality and reliability in electronic devices.

Automotive: Used to clean parts before painting, bonding, or sealing, plasma cleaners improve surface adhesion and product durability in automotive manufacturing.

Aerospace: Plasma cleaning plays a key role in preparing composite materials for bonding, ensuring strong adhesion in critical aerospace components.

Biomedical: In medical device manufacturing, plasma cleaning ensures that surfaces are free from contaminants that could interfere with sterilization or cause reactions in clinical use.

In conclusion, the plasma cleaning process offers an advanced, eco-friendly solution for surface treatment across many industries, ensuring deep and precise cleaning that is impossible with traditional methods. Its advantages in terms of precision, environmental sustainability, and material compatibility make plasma cleaning an essential tool for any industry, requiring high cleanliness standards and optimal surface preparation. With the continuous development of new plasma technologies, it is likely that in the coming years we will see a further increase in its applications.

FAQ – Plasma cleaning

How does plasma cleaning work?

Plasma cleaning works by generating a plasma, typically from gases like argon or oxygen, which ionizes and creates a mixture of high-energy particles. These particles bombard the surface of a substrate, physically removing contaminants through ion bombardment, while chemically reacting with organic residues to turn them into gases that are then expelled.

How long does plasma cleaning last?

The effects of plasma cleaning last as long as the substrate remains uncontaminated. However, surfaces can begin accumulating contaminants from the environment over time, so the duration of the cleaning effect depends on the surrounding conditions.

Is plasma cleaning safe?

Yes, plasma cleaning is safe when used properly. It is a non-contact, chemical-free process, reducing exposure to harmful substances.

Is plasma cleaning hot?

No, plasma cleaning is cold, it occurs at low temperatures.

Is plasma cleaning effective?

Yes, plasma cleaning is highly effective. Plasma gas removes both organic and inorganic contaminants from a surface, preparing it for further processing or coating with a high degree of cleanliness and precision.

What does oxygen plasma treatment do?

Oxygen plasma treatment removes organic contaminants by oxidizing them, converting them into gases such as carbon dioxide and water vapor, which are then removed. It also increases the surface energy of materials like polymers, improving adhesion for bonding and coating applications.

What is plasma surface treatment?

Plasma surface treatment modifies the surface properties of a material. It can clean, etch, or activate a surface to improve its adhesion, wettability, or bonding capacity, making it suitable for further processing like coating or bonding.

What is plasma cleaning process?

The plasma cleaning process involves placing a material into a chamber where a plasma, typically generated from gases like argon or oxygen, interacts with the surface. The energetic ions physically remove contaminants while reactive species chemically convert organic residues into volatile compounds that are expelled from the system.

What is a plasma cleaner used for?

A plasma cleaner is used to remove contaminants, such as oils, organic residues, or other surface impurities, from a wide range of materials including metals, polymers, glass, and ceramics. It is commonly used in industries like electronics, automotive, aerospace, and biomedical.

What does plasma treatment do to glass?

Plasma treatment on glass removes organic contaminants and increases the surface energy, improving adhesion for coatings, bonding, or printing. It can also etch or activate the surface for specific applications.

What is plasma cleaning in semiconductor?

In the semiconductor industry, plasma cleaning is used to remove organic and inorganic residues from wafers, masks, and other components. It ensures a clean surface for lithography, deposition, and etching processes, critical for high-performance semiconductor devices.

What is the pressure for plasma cleaning?

Plasma cleaning is typically performed under low-pressure conditions, usually in the range of 0.1 to 1 torr, to ensure efficient plasma generation and interaction with the surface.

What is the difference between laser and plasma cleaning?

Laser cleaning uses focused laser beams to remove contaminants through thermal ablation or vaporization, whereas plasma cleaning uses ionized gas to physically and chemically remove surface impurities. Plasma cleaning is better suited for delicate materials, while laser cleaning is effective for more robust applications.

What are the advantages of plasma cleaning?

Advantages include:

- Non-contact, precise cleaning

- Environmentally friendly (no chemical solvents)

- Effective on a wide range of materials

- Enhances surface adhesion

- Low-temperature process, safe for sensitive materials

What gas is used in plasma cleaning?

Common gases used in plasma cleaning include oxygen, argon, nitrogen, hydrogen, and air. The choice of gas depends on the type of contaminants and the material being cleaned.

What is the theory of plasma cleaning?

Plasma cleaning is based on the principle of ionized gas interacting with a material’s surface. High-energy ions physically bombard the surface, while reactive species chemically break down contaminants, transforming them into gases that are expelled.

What materials are used in plasma cleaning?

Materials commonly cleaned with plasma include metals, polymers, ceramics, and glass. Plasma cleaning is effective across a wide range of materials due to its non-contact and low-temperature nature.

Why is plasma cleaning important?

Plasma cleaning is important because it ensures surfaces are free of contaminants, improving adhesion, coating performance, and overall reliability in applications like electronics, medical or dental devices, and aerospace components.

Can you put plastic in a plasma cleaner?

Yes, plastic can be cleaned in a plasma cleaner. Plasma cleaning is safe for many types of plastics due to its low operating temperature, and it effectively removes surface contaminants.

Can you put metal in a plasma cleaner?

Yes, metals can be cleaned in a plasma cleaner. Plasma is effective in removing oxides, organic residues, and other contaminants from metal surfaces.

How long does plasma cleaner take?

The duration of a plasma cleaning cycle varies depending on the material and the level of contamination, but it typically ranges from a few minutes to about 30 minutes.

How to operate plasma cleaner?

To operate a plasma cleaner, load the substrate into the chamber, select the appropriate gas and pressure settings, and initiate the plasma. After the cleaning cycle is complete, the system will evacuate the gases, leaving a cleaned surface.

What frequency is plasma cleaner?

The frequency used in plasma cleaners typically ranges from 13.56 MHz (RF) to 2.45 GHz (microwave), depending on the type of plasma system and application.

What is plasma cleaning machine?

A plasma cleaning machine is a device that generates plasma from a gas, using it to clean and prepare the surface of materials by removing contaminants.